Multi-purpose

HARDI mistblowers lets you spray without compromise – all your different crops. Whatever you grow – from small bushes to large tree plantations.

Robust and simplicity

Benefit from the expertise gained with HARDI’s many years of worldwide experience in orchard spraying. Everything from tank design and built to the latest electronic control systems is reflected in our sprayers.

Air kits & deflectors

The Air Kits offer better air distribution, higher airflow, a lower noise level, and less power consumption - all together to provide you with a first-class application.

The fan housing is made of high-impact polyethylene and incorporates a unique channel plate that makes the air production much more uniform. The fan blades are made of polymer, a very strong synthetic material, and can be adjusted in order to adapt the air volume to the individual orchard.

The air kits are fitted with double, non-drip nozzle holders situated outside the airstream.

HARDI’s special deflectors help you optimize and adapt the generated air to your specific crop and working conditions.

Tanks

Available in tank sizes 1500, 2000 & 3000 l. The tanks are made of high-impact polyethylene and are resistant to plant protection chemicals.

Features:

UV-resistant

Good stability as the overall design ensures a low centre of gravity

Main tank has an overcapacity of 5%, making filling a safe task

15 litre hand wash tank

Available with or without Rinse Tank and Tank Flush Nozzles

Tank contents indicators situated in the front and on the side of the tank

Top operated drain valve in the sump of the tank

Efficient Venturi agitation

Powder mixer placed in the filling strainer

Tank warranty - 5 years under normal working conditions

Chassis

The chassis is made of special UPN steel profiles providing robust durability and resistance to vibrations. The design and construction prevent accumulation of dirt and thereby prevent corrosion.

The chassis is protected with a top of the line powder paint surface treatment which includes

Steel bullet grinding of all steel parts

Pretreatment tunnel with 4 different “showers” which removes possible grease and applys anti-oxidation such as zinc, phosphate acids and nano ceramic.

Parts enter the drying oven, and continue towards the painting line, where the powder is applied.

Parts enter a 200º oven to convert the applied powder to a top professional surface protection, which we also call powder paint.

All mistblowers are also built with DELTA TONE ® treated bolts and nuts, to give this small, but important, part of the machine a much needed anti-corrosion nuts and bolt.

Pumps

The diaphragm pumps are designed for the application of plant protection products. The diaphragms separate the liquid from the vital parts of the pump such as its bearings and crankshaft, ensuring reliable and durable operation.

HARDI diaphragm pump features:

Self-priming

Able to run dry without damage

Grease-lubricated crankcase

Chemical resistant diaphragms and valves

Able to rotate clockwise or anti-clockwise

Easy to service without special tools

Control unit

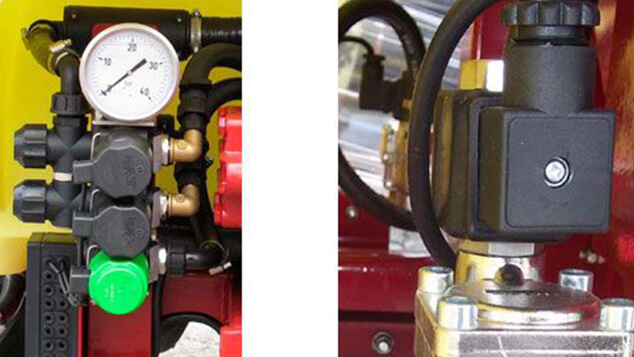

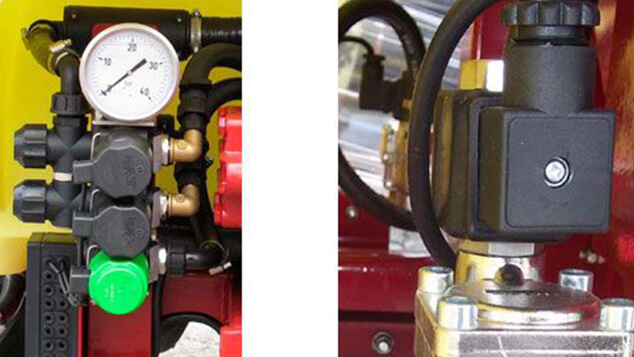

CB/2 & CB/4 control unit

The CB has electrical remote control of all functions and is available with 2 or 4 distribution valves. The pressure regulation valve is made of stainless steel for maximum resistance to aggressive products, and the rest of the vital parts are completely sealed off from the spray liquid. The CB unit includes pressure equalization device and pressure gauge. Maximum working pressure is 20 bar. Can optionally be fitted with a HARDI CONTROLLER.

SV/2 control unit

Solenoid valves operate the SV control. It has two distributors that are remotely controlled. Manual pressure regulation. A HARDI CONTROLLER can be fitted as an option.

Mixing with TurboFiller

Filling, mixing and loading your trailed mistblower exceed every standard with the compact TurboFiller.

Undiluted liquid formulations are induced safely and at speed. Dry formulations can be premixed and induced too. No mess, no hold back, no spills, no need for buckets and stirring sticks.

Operator and environmental safety have first priority.

Email us

Email us for general queries, including Products and Spare parts..

sales@hardi.co.ke

Call us

Call us to speak to a member of our team.We are always happy to help you.

Support

Technical support for each product is given directly by our technical and sales team